The primary cause of spalling in concrete is – Spalling in concrete, a pervasive issue that undermines structural integrity, has its roots in a complex interplay of factors. This article delves into the primary cause of spalling in concrete, examining the mechanisms behind this damaging phenomenon and exploring strategies for prevention and repair.

Moisture and freeze-thaw cycles, chemical reactions, mechanical stress, poor construction practices, environmental factors, and design considerations all contribute to the development of spalling. Understanding the role of each factor is crucial for mitigating its effects and ensuring the longevity of concrete structures.

Moisture and Freeze-Thaw Cycles

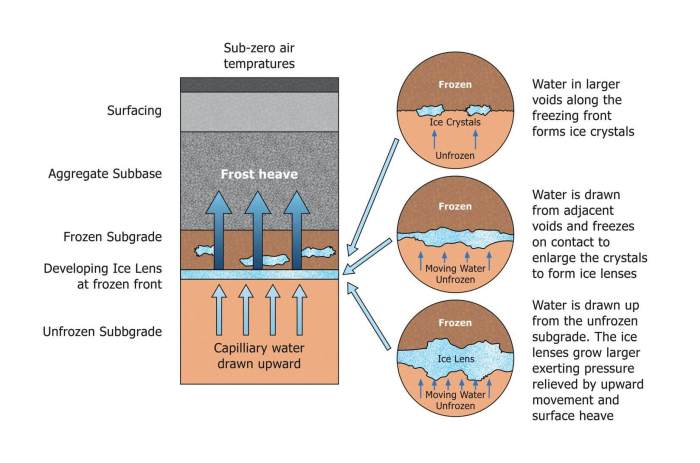

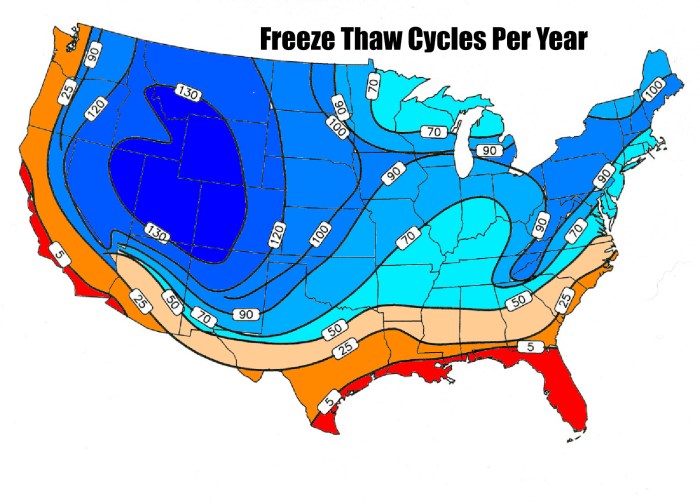

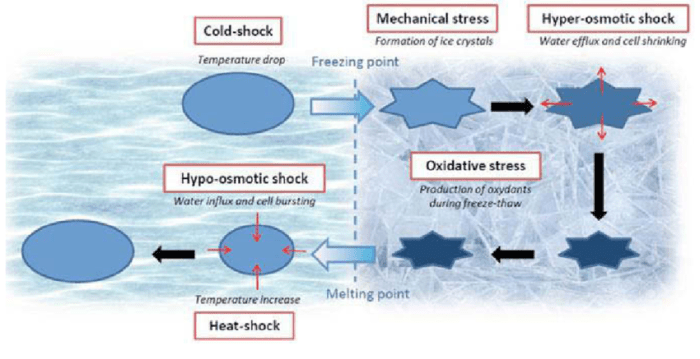

Moisture absorption and freezing can lead to spalling when water penetrates into the concrete pores and freezes. As water freezes, it expands, creating internal pressure that can cause the concrete to crack and break away. The severity of spalling depends on the moisture content of the concrete, the freezing temperature, and the number of freeze-thaw cycles.

Effects of Different Moisture Levels and Freezing Temperatures

Higher moisture content increases the risk of spalling because more water is available to freeze and expand. Lower freezing temperatures can also lead to more severe spalling because the ice crystals formed are larger and exert greater pressure on the concrete.

Chemical Reactions

Certain chemical reactions within concrete can also cause spalling. These reactions can involve alkalis, sulfates, or other substances that react with the concrete components, leading to expansion and cracking.

Role of Alkalis, Sulfates, and Other Substances

Alkali-silica reaction (ASR) occurs when reactive silica in the concrete reacts with alkalis in the cement, causing the formation of a gel that expands and cracks the concrete. Sulfate attack occurs when sulfates from external sources, such as groundwater or seawater, penetrate the concrete and react with the cement, forming expansive compounds.

Mechanical Stress

Mechanical stress, such as loading and vibration, can contribute to spalling by creating cracks or weakening the concrete. These cracks can then provide pathways for moisture and chemicals to penetrate, leading to further damage.

Effects of Different Types of Stress

Static loading, such as the weight of a building, can cause compressive stress in the concrete, leading to cracking and spalling. Dynamic loading, such as vibrations from machinery or earthquakes, can cause tensile stress in the concrete, also leading to cracking and spalling.

Poor Construction Practices

Poor construction practices can significantly increase the risk of spalling. These practices include inadequate curing, improper compaction, and poor material selection.

Effects of Inadequate Curing, Improper Compaction, and Poor Material Selection, The primary cause of spalling in concrete is

Inadequate curing prevents the concrete from gaining sufficient strength, making it more susceptible to cracking and spalling. Improper compaction can lead to voids and honeycombs in the concrete, providing pathways for moisture and chemicals to penetrate. Poor material selection, such as using low-quality aggregates or cement, can result in a weaker concrete that is more prone to spalling.

Environmental Factors

Environmental factors, such as temperature fluctuations, humidity, and exposure to chemicals, can influence the durability of concrete and increase the risk of spalling.

Effects of Temperature Fluctuations, Humidity, and Exposure to Chemicals

Rapid temperature fluctuations can cause thermal stresses in the concrete, leading to cracking and spalling. High humidity can promote moisture absorption, increasing the risk of freeze-thaw damage. Exposure to chemicals, such as acids or salts, can react with the concrete components, causing deterioration and spalling.

Design Considerations: The Primary Cause Of Spalling In Concrete Is

Proper design considerations can help prevent spalling by reducing the risk of moisture penetration, chemical reactions, and mechanical stress.

Importance of Proper Drainage, Joint Design, and Reinforcement

Proper drainage systems prevent water from accumulating around the concrete, reducing the risk of moisture absorption and freeze-thaw damage. Joint design allows for expansion and contraction of the concrete, preventing cracking and spalling. Reinforcement, such as steel bars or fibers, strengthens the concrete and reduces the risk of cracking under mechanical stress.

Repair and Prevention Strategies

Repairing spalled concrete and preventing further damage involves using patching materials, sealants, and protective coatings, as well as improving drainage and reducing moisture penetration.

Use of Patching Materials, Sealants, and Protective Coatings

Patching materials fill in the spalled areas, restoring the structural integrity of the concrete. Sealants prevent moisture and chemicals from penetrating the concrete, while protective coatings provide a barrier against environmental factors.

Strategies for Improving Drainage and Reducing Moisture Penetration

Improving drainage involves installing proper drainage systems to prevent water from accumulating around the concrete. Reducing moisture penetration can be achieved by using waterproof membranes, sealers, or coatings to prevent water from entering the concrete.

Clarifying Questions

What are the main causes of spalling in concrete?

The primary causes of spalling in concrete include moisture and freeze-thaw cycles, chemical reactions, mechanical stress, poor construction practices, environmental factors, and design considerations.

How can moisture and freeze-thaw cycles lead to spalling?

Moisture absorption and freezing can cause concrete to expand and contract, creating internal stresses that weaken the material and lead to spalling. The presence of deicing salts can exacerbate this process.

What role do chemical reactions play in spalling?

Chemical reactions, such as the alkali-silica reaction and sulfate attack, can cause concrete to expand and deteriorate, leading to spalling.

How can mechanical stress contribute to spalling?

Mechanical stress, such as loading and vibration, can cause concrete to crack and weaken, making it more susceptible to spalling.

What are some poor construction practices that can increase the risk of spalling?

Poor construction practices, such as inadequate curing, improper compaction, and poor material selection, can weaken concrete and increase the risk of spalling.